The pump re-launches the fluid towards the mixer also called CEDAR (20). In the piping between the mixer and the pump there are the magnetic filter (14), the flow meter (18), the first temperature sensor (19) as well as the inlet cannulas of the standard ozonator (15) of the second ozonizer (16) and an optional insufflator (17).

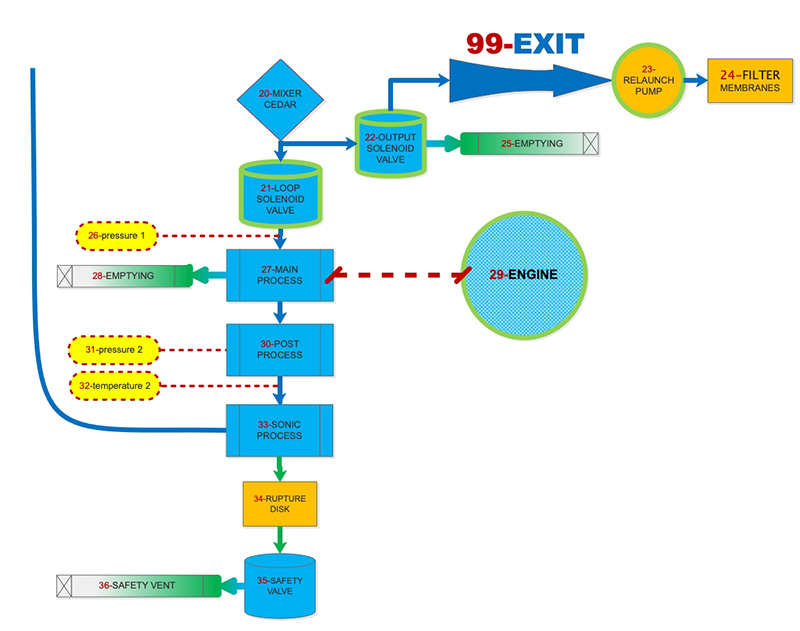

At the mixer outlet, the fluid can either continue the loop passing a special solenoid valve (21) or exit (99) from the machine passing another solenoid valve (22) beyond which one or more booster pumps (23) can be optionally placed as well as membrane filters (24). The outlet, being at the lowest point, is also used to empty the machinery (25) if it is necessary to clean it.

Beyond the valve that enters the loop, after the pressure control (26), the fluid enters the main process (27), which can be completely emptied by means of a special manual faucet (28) accessible from the outside, on which it is also connected the engine (29) of the device. At the outlet, the fluid passes into the post process (30) where both the temperature (32) and the pressure (31) are metered and from there into the sonic process (33) where the fluid undergoes the last treatments, observable through a porthole in glass, to then return to the tank.