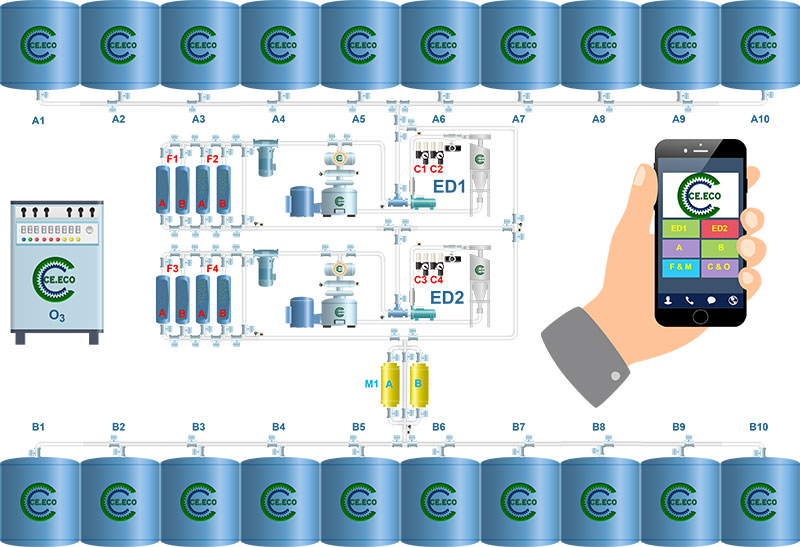

The water produced by the plant or brought to a treatment center equipped with our system, after having been withdrawn from the storage silos (A1-A10) undergoes a first cavitation treatment (ED1) with or without the addition of chemicals (C1-C2) and ozone (O3).

Subsequently the fluid, relaunched if necessary with a pump, can be either filtered (F1-F2) or, through a bypass, continue its course.

Each filter can be duplicated in parallel (A-B) in such a way that if the sensors should notice a decrease in efficiency, the staff will immediately be notified to intervene on the cartridge to be regenerated or replaced.

Based on the needs, the fluid can undergo a subsequent cavitation in the second EMPOWERING DEVICE (ED2) which will be equipped exactly like the first: chemicals pumps (C3-C4), ozone (O3), filters (F3-F4) duplicated in parallel (A-B), bypass and booster pump.

Similarly, for what happens at the exit of the first EMPOWERING DEVICE the fluid can at this point be sent back to the first or second cavitator to undergo further treatments or, if now considered purified, be sent directly or through osmotic membranes (M1) duplicated in parallel (A-B), towards the final storage silos (B1-B10). Even with membranes, should the sensors detect a decrease in efficiency, the staff will immediately be notified to intervene on the cartridge to be regenerated or replaced.

From the definitive storage silos, after sample analysis, following the provisions and limits of the law, the water will either be discharged into the sewer or into a ditch or even reused to water the surrounding fields.

Below a water treatment plant developed around a couple of EMPOWERING DEVICE.