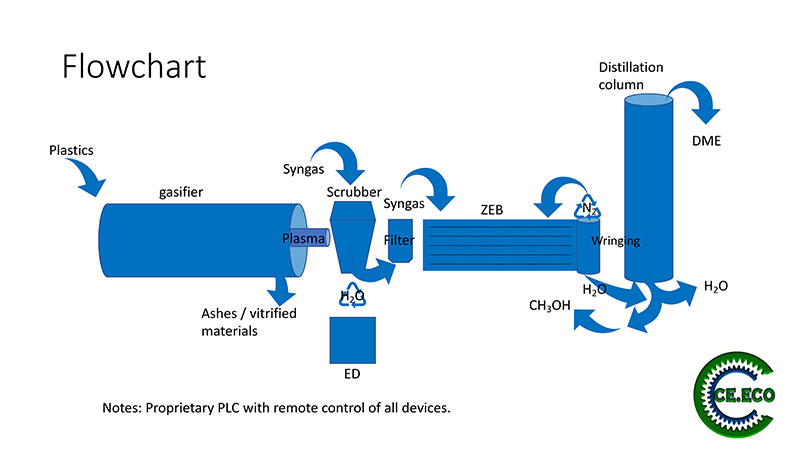

Our system consists of a fluidized bed rotary furnace combined with a plasma placed in the queue for the vitrification of the aggregates. Schematically the rotating tube can be divided into three zones: in these three different reactions can take place. Furthermore, the system that supplies the oxidant for the reactions can be installed at will in one area or another allowing the differentiation of application mentioned above.

The type of oxidizer can be air, oxygen or water vapor and the entire tube can be brought to operating temperature using gas torches.

If a process based on combustion was necessary, we would place the system that provides the oxidant for the reactions in the first part of the tube thus providing an excess quantity of air and thus favoring the combustion of the organic material - understood as a substance carbon base.

Depending on the needs, the system that supplies the oxidant for the reactions could instead be placed in the final part of the tube: by heating the tube it allows pyrolysis to be obtained in the first part, reduction in the central part and combustion in the final part. The resulting products of the entire process are ashes which will be vitrified and then inertized using a plasma placed at the end. The heat generated can be used for the production of electricity. If the air is supplied in the first part, all the heat is supplied by the material to be treated.

If a process based on pyrolysis is necessary, the tube will be heated using gas torches and brought to a temperature of 500-600°C depending on the material to be treated. The resulting products are bio-oil (similar to diesel produced with the Fisher-Tropsch reaction), coal and gas, the latter can be used to heat the system. In this case there is no oxidizing agent and the organic molecules are split thermally.

If a process based on gasification is necessary, the system that supplies the oxidant for the reactions will be positioned in the central part, the quantity of oxidant will be stoichiometric, the tube will be heated to the reaction temperature, i.e. above 900°C.

With this treatment process the main product obtainable is syngas.

The degree of purity of the gas depends on the oxidizer used. By using air, the gas that will form will have a high percentage of nitrogen which will lower its calorific value; using steam, the gas that will be formed will have both high calorific value and purity, allowing easy use of the gas for the synthesis of chemicals; using oxygen instead, the gas formed will have median values.

In the first part of the tube we will have pyrolysis of the material, in the central part there will be partial oxidation and in the final part there will be a reduction of the gas produced.