Our process accelerator can be placed, according to the process needs, at the entrance, in recirculation or at the exit of a tank.

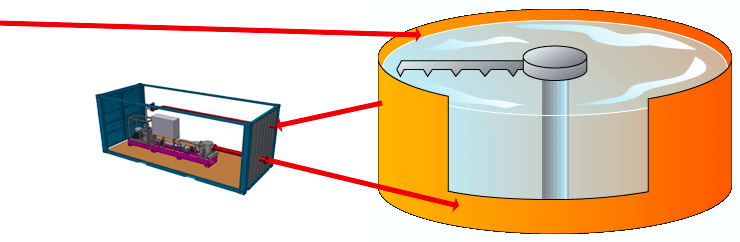

in recirculation (loop): a pump sucks the liquid matrix from the treatment tank, sends it to the EMPOWERING DEVICE for treatment and returns it to the treatment tank through a second access pipe. With this configuration, it is possible to treat and improve the functioning of an existing plant, reducing any accumulations of fibrous fractions of the non-degraded matrix quickly enough.

PRO: Implementation costs are reduced to a minimum and existing plants can process significantly higher quantities of matrices before being scaled down or supported by further plants. This location has the disadvantage that part of the fluid will be treated several times.

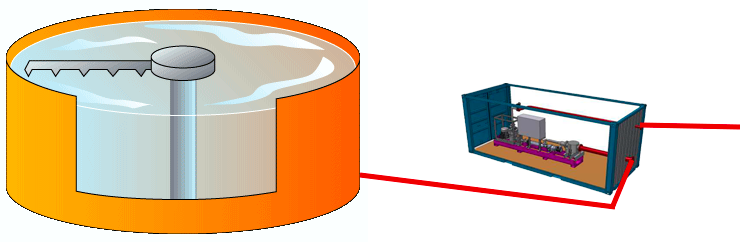

at the exit of the primary treatment tank: configuration similar to the previous one, the main difference consists in treating the product only once and discharge it into a second tank where it shall receive a subsequent treatment.

PRO: In addition to maximizing the efficiency of the second tank where the matrix will receive a subsequent treatment, this location allows the inertization of the microbial charges of the matrix. This location has the disadvantage that the time used to treat the fluid in the first tank still be the same.

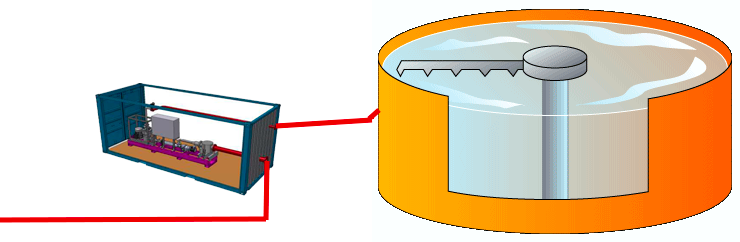

for the input matrix treatment: the matrix at the load can be mixed with a hydraulic vector and sent to the cavitator for disintegration before loading. Depending on the type of plants, the type of matrices used and the intensity of the treatment to be obtained, the technology can be applied on the whole loaded matrix or only on a part (EXAMPLE in biomasses typically those characterized by fibrous matrices and particularly complex to degrade).

PRO: In this configuration, the efficiency of the cavitator is maximized if cavitation is applied to the whole matrix. This location can bring the greatest advantages.