The collection trucks that will enter the sorting area, in depression, through a double-door decompression gate that prevents the escape of any emissions and odor molecula.

Inside the depression area, the materials, before becoming the matrices to be used, they will undergo some mechanical pretreatment processes.

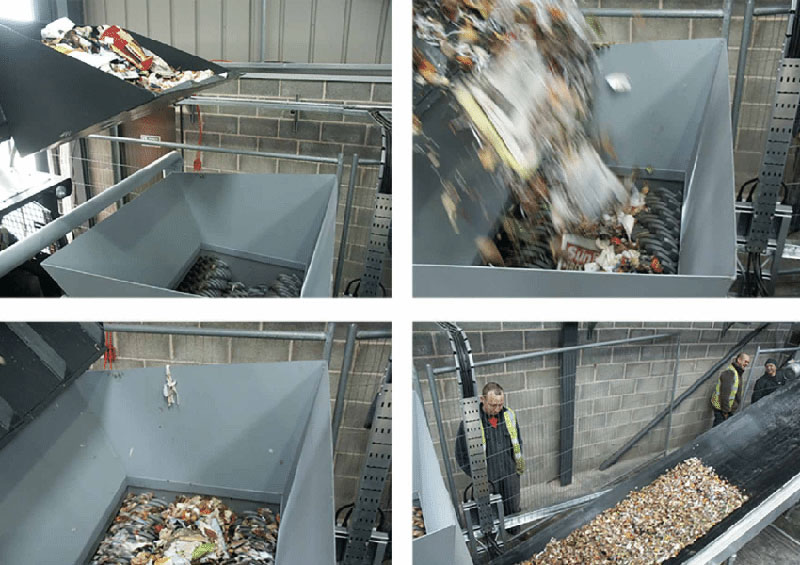

We will start with a dimensional reduction (shredding) which allows to reduce the size of the waste in order to facilitate downstream treatment operations.

A separation cycle will then follow which will exploit the different physical properties possessed (dimensions, density, magnetism, optical properties, etc.). The waste will be subjected to successive selections in cascade in order to obtain single products with acceptable degrees of purity. Everything that can be recycled in other processes (metals and glass essentially) will be discarded in this phase as well as fragments of ceramic, masonry and anything that is not organic will be eliminated.

Excess moisture will be eliminated by drying which uses part of the excess heat generated by gasification.

A second shredding cycle, also by means of a ball mill if the type of matrix makes it necessary, will reduce the matrix to extremely small and homogeneous dimensions.

If required, the matrices not discarded from the previous separation can be compacted and briquetted in order to build up stocks for a more homogeneous subsequent use.